Inspection Services

All measuring equipment and gages used to inspect product have been verified with calibration masters that are traceable to NIST.

Calibration gage blocks are Grade 0 (Laboratory Grade) and are only used for calibration of instruments. Calibration gage blocks are scheduled to be recalibrated on 01/2018.

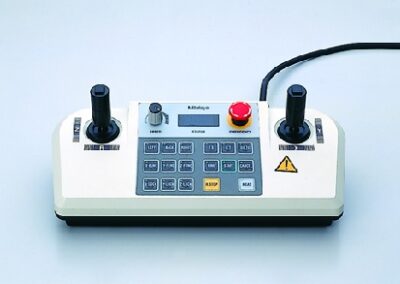

Mitutoyo CRYSTA-Apex S776 CNC Coordinate Measuring Machine w/motorized probe head

The challenges for measurement equipment are rising. Products are continuously improving as a result the lifetime of products is increasing while their energy consumption is reduced. Additionally, the throughput of production is driven up. All these facts must be taken into account for your measuring equipment. With the STRATO-Apex CMM, Mitutoyo offers you the opportunity to match both: precision and velocity.

This high accuracy CNC coordinate measuring machine that allows very accurate results at lightning speed.

The STRATO-APEX Series offers you the following benefits:

•High measurement accuracy and high-speed motion

•High-performance scanning

•Ultra high precision scales on each axis

•Anti-vibration system reduces the impact of nearby vibration sources (optional for 574)

•Multi-sensors capability

Features

Model: 776

Range: 700 x 700 x 600 mm

27.56″ x 27.56″ X 23.62″

Loading

Weight: 500 kg / 1100LBS

Mass: 1895 kg / 4175LBS

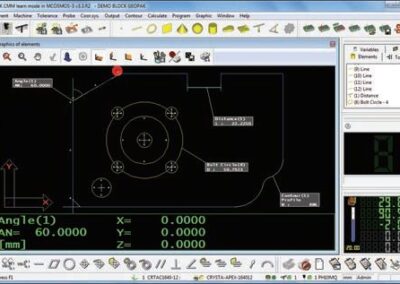

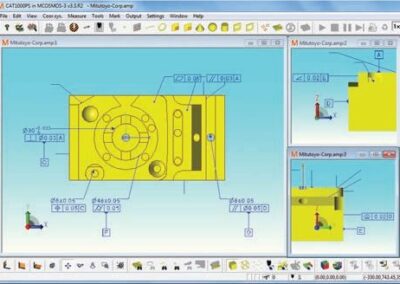

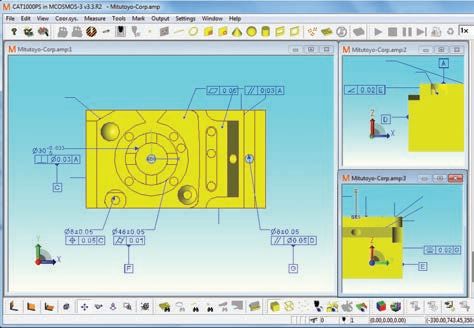

Mitutoyo MCOSMOS, CAT 1000, and Geopak CMM Software

Cat-1000 CaD Interface

CAT1000 significantly facilitates the programming of measurement tasks during the GEOPAK learn mode. All data for measuring parts and tolerance evaluations are taken accurately from the CAD model via pointing device (mouse, trackball, etc.) selection. The same principles apply for programming probe paths (clearance and measurement), while at the same time, using the nominal directly off the CAD model for tolerance comparison.

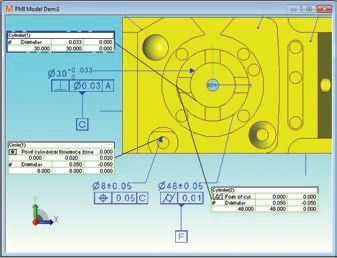

Product Manufacturing Information

CAT-1000 uses 3D ACIS® Modeler is Spatial’s prominent modeling component used in over 350 customer applications with more than 2 million seats worldwide.CAT-1000 fully supports and reads PMI (Product Manufacturing Information) which is imbedded in the model for Datum alignment, GD&T Geometric Dimensioning and Tolerancing. Spatial’s 3D InterOp delivers the highest quality data exchange between CAD formats, enabling superior CAD file translation. The comprehensive suite of translators provides import/export for all applications, including ACIS, CGM and Parasolid-based applications. 3D InterOp is embedded in many of today’s leading design, engineering, and manufacturing applications.

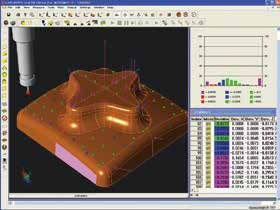

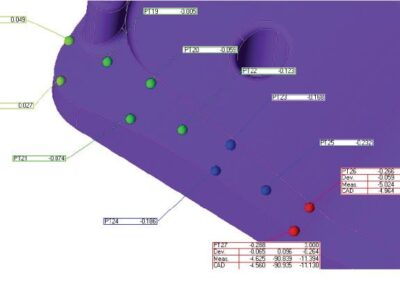

Cat-1000 3D surface analysis

CAT-1000 CNC can create grid patterns to verify the surface, Simple one click tool calculates a collision free probe path to measure a grid of surface points.Manual CMMs allow the operator to move the probe manually and the point will appear real-time. Probe compensation is determined from the center of the stylus and the shortest distance to the CAD model to eliminate cosine error.

Surface deviation can be displayed as spherical points or as a gradient surface.Cones can be used to show what direction the surface vector of material from the nominal and given tolerance.

GEOPAK CNC

GEOPAK (Basic Geometry module) provides an easy graphical console to the operator by the use of tool bars and windows which can be personalized to the operator’s preference.GEOPAK provides visual tools, completely eliminating the use of difficult codes or abbreviated commands as other packages use. Its graphically enhanced display provides step-by-step, on screen wizards that prompt the operator, allowing even inexperienced users to create routines to measure parts.Our basic level software includes the flexibility for advanced tools demanded by the most experienced operators; e.g. looping, formula calculations or expressions that use variables, libraries of day to day sub-routines and conditional statements which add logic for wide variety of applications.

5In GEOPAK there is no limit to your reporting capabilities, we have created a series of templates that are ideal for typical applications, but if a custom report is needed, our Protocol-Designer allows the operator to customize the output to any format desired.The Protocol Designer can be used to eliminate the need to transpose the GEOPAK results to a separate spreadsheet, document that your customer may require, e.g. AS9102. Forms can be created and saved as templates so the data from GEOPAK auto-fills the report after executing the part program.When a template is used for output the operator can chose a variety of formats such as Adobe PDF, Microsoft Excel and save the results to a server or the local printer.

Starrett HDV300

Wirtz Wire EDM, LLC utilizes an innovative new system combining the power of the Optical Comparator with digital video, hi-resolution cameras, telecentric optics, and LED illumination: the HDV300 from Starrett

The HDV-300 incorporates a digital overlay part design file (DXF) for comparing the inspected part to its design profile, similar to using a Mylar overlay chart on a comparator screen.

Intuitive M3 programming power and simple operator display interface make part measuring efficient and highly productive.

Features & Specifications:

- Large measuring travel

- Quick action interchangeable lens system

- Rugged design suitable for many manufacturing environments

- Benchtop mounting

- DXF CAD import and overlay measurement software

- 24″ touch screen monitor

- LED illumination