Wire-EDM, Conventional EDM, and EDM-Drilling.

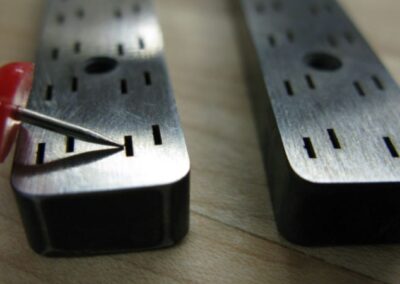

Wire-EDM

Our high accuracy wire-EDM machines position to the thousandth of a micron using glass scales for closed loop, true positioning accuracy. Part accuracy is simply incredible!

Touch screen, thermal compensation, servo water level control, Ethernet drag and drop programming as well as remote monitoring of the machine from the control.

The machines can automatically determine the thickness of the part while cutting, virtually eliminating wire breaks while increasing accuracy. The features of this new machine are drastically improved from our five-generation old machines that we started our EDM business with.

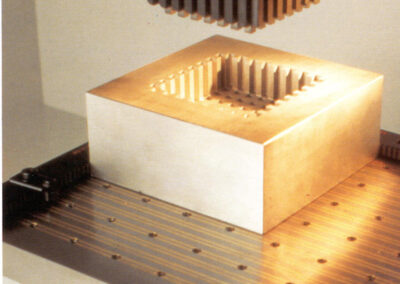

Conventional (Ram)-EDM

(Sinker) with (16) position electrode changer, System 3R Combi Tooling including Macro, Macro Junior, and 20mm shank electrode holers. 60 amp, capable of finishing down to RA 3 (mirror).

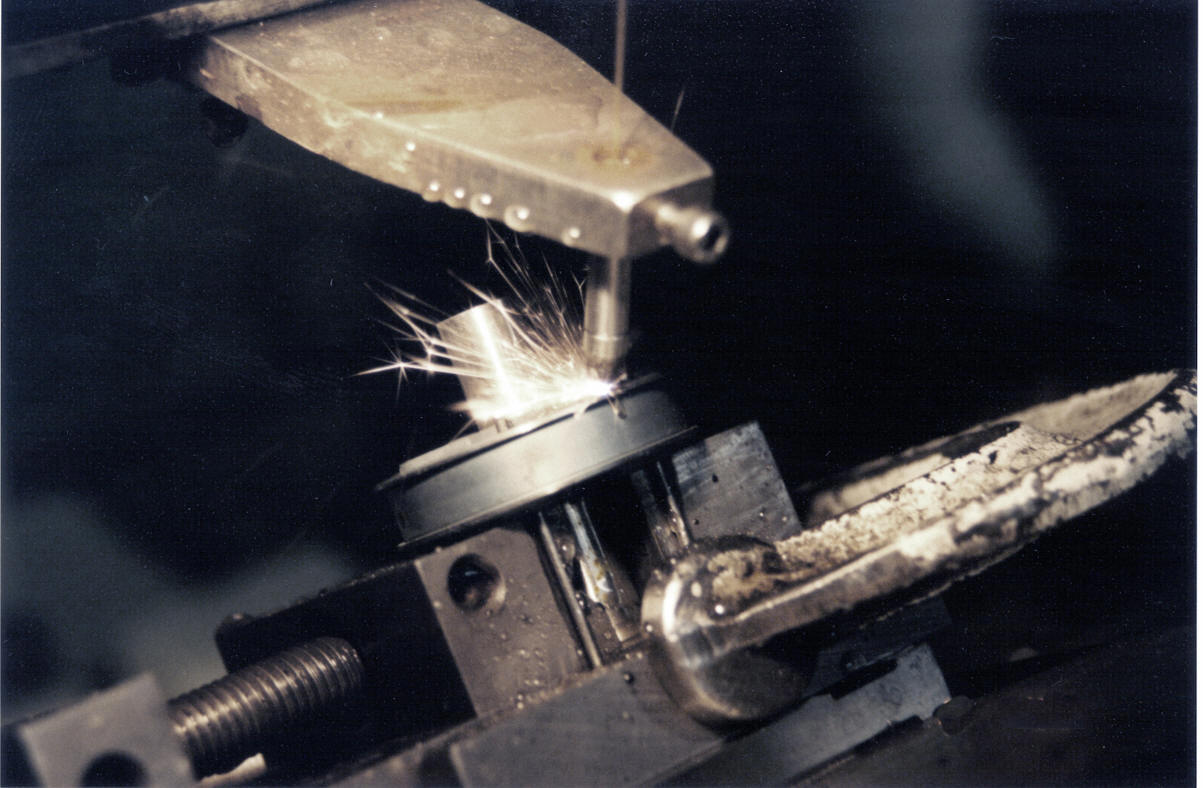

EDM-Drilling

With extended 20? tall workpiece capacity. 13.7? X 9.8? table travel and 12? X 24? workpiece size. Hole drilling capability from .008? dimaeter electrode to .118? diameter electrode. Drills quickly thru hardened steel, carbide, exotic alloys, etc.